Everything you need to know when upgrading or replacing your elevator

The function of an elevator is simple: to move people or products vertically through a building with multiple levels. Yet elevators are among the most complex equipment systems in modern buildings.

Building owners considering the integration of elevators into their projects often need guidance when evaluating the benefits and drawbacks associated with choosing elevator systems. This article is geared towards helping those who are considering an elevator project and are trying to understand contemporary elevator system basics with an emphasis on passenger elevators. The information is intended to be used for general reference only, so be sure to consult with a design professional to determine what’s best for your project.

Unlike most building equipment, elevators require the integration of every major building system including structural, mechanical, electrical, plumbing, fire alarm, and fire suppression systems.

Why do I need an elevator?

Transportation of people // Accessibility + ADA compliance // Fire protection + evacuation

There are many situations where having an elevator makes sense – and there are many more situations where having an elevator is required for building code compliance. The most common (and obvious) reason for wanting an elevator is to move people or products for convenience. Apart from convenience, an elevator may be required for building code compliance to ensure that your building is accessible to persons with disabilities. For buildings that are between two and four stories above grade, an accessible route can be provided by specially designed stairs, ramps, or an elevator. In most cases, if the building is four or more stories above grade, then it will require an elevator for accessibility. In high rise buildings, elevators may also be required to help fire fighters during emergencies or to help evacuate the building with specialized occupant evacuation elevators.

What kind of elevator do I need?

Elevator systems should be carefully selected based on various considerations, including those described in this article. Before discussing elevator systems in detail, we’ll first describe a few simple circumstances applicable to many building owners. Let’s assume that a building owner wants to move passengers or lightweight supplies vertically through the building and that the only criteria for selecting the elevator system are budget and technical feasibility or practicality. Given these basic assumptions, you can generally use the number of stories served to select an elevator system type as follows:

2–3 floors: Hydraulic elevator (holed or hole-less)

4 floors: Holed hydraulic elevator or machine room-less traction elevator

5–25 floors: Machine room-less traction elevator

25 or more floors: Machine room traction elevator

The number of stories served in a given situation may be somewhat more or less than described above depending on the floor-to-floor height of the individual building and the elevator manufacturer selected. There are also many other factors that can influence the final elevator selection, including desired speed, traffic analysis, noise requirements, ride quality, load requirements, energy use, life-cycle cost, maintenance requirements, building types, and more. But for many building owners, this is a good place to start. This article will delve into a bit more detail for the interested building owner.

Terms to know when discussing elevators:

Car

Also known as a cab, this is the vessel for moving people and products vertically in a building. The car travels within the hoistway, guided by rails vertically, and moved vertically by an elevator machine system.

Hoistway

Also referred to as an elevator shaft, it is the vertical enclosure through a building that contains the elevator car or cars.

Pit

A space within a hoistway located between the lowest floor landing served by the elevator and the hoistway floor. The pit is used to contain essential elevator equipment and is necessary space for the proper and safe performance of the elevator.

Travel Height

The amount of distance that the elevator car needs to travel to serve the lowest and highest landing in a building. This is similar to the number of floors served, except that floor-to-floor height varies from building to building. Thus, the actual travel height is a better marker.

Overhead

A space within a hoistway located between the highest floor landing served by the elevator and the hoistway ceiling. Overhead height is required to allow room for elevator equipment and to provide necessary space for the proper and safe performance of the elevator.

Wait Time

The time it takes for the elevator to answer your call from the moment you call the elevator.

Bank

A group of two or more elevators served by a single call station.

Elevator System

A complete system required for the building code compliant operation of an elevator conveying system, including architectural, structural, electrical, mechanical, plumbing, technology, fire protection, and fire suppression support systems.

What types of elevators are there?

The four categories of elevators available are referred to as passenger elevators, freight elevators, limited use limited application elevators (also known as LULA’s), and residential elevators.

Passenger Elevators

small loads

25–55 square feet

As the name implies, a passenger elevator is designed to move people or lightweight supplies for convenience, accessibility, or for life safety functions. Passenger elevators are conventionally rated for between 2,000 and 5,000 pound weight loads, though some are available with higher load ratings after customization. In terms of dimensions, these weight ratings translate into car dimensions that are between 25 and 55 square feet.

Freight Elevator

large industrial loads

customized to support equipment being transported

size depends on cargo

A freight elevator is used for moving large or heavy industrial loads and equipment only. Freight elevators can be enormous when used for moving cars or industrial machines, or can be similar in size to a passenger elevator. Building owners sometimes mistakenly refer to passenger elevators as freight elevators when they use the elevator to move lightweight supplies in private building spaces, but true freight elevators cannot be operated in the same way as passenger elevators. Freight elevators typically require separate buttons to call the car, open the doors, close the doors, etc. In other words, a freight elevator is less automated to give the user greater control over the elevator operations. If you have ever seen an elevator door that opens vertically, has a cage door, and has durable but unattractive finishes, then you have probably seen a freight elevator. In addition, freight elevators must be specified to handle the anticipated loads. This includes considering the method in which a cab is loaded (such as by a heavy forklift) and whether the load on the elevator platform is evenly distributed or eccentric.

Lula Elevator

small passenger-style elevator

2-3 stories maximum

affordable; minimal overhead

slow: 30 ft rise / second

fewer building related requirements

A LULA elevator is small passenger-style elevator intended for limited applications. Typically a LULA can serve a maximum of two or three stories, with a cab only large enough for a single wheelchair. LULA’s are also slow and operate at about 30 feet of rise per second. Apart from the smaller size and ability to only serve a few levels, a LULA is otherwise operated in the same fashion as a passenger elevator with many of the same options. LULA’s are often sought after for their lesser cost and for having fewer building related requirements, such as shallow elevator pits and minimal overhead requirements.

Residential Elevator

smallest of all elevators

single-family residence only

Finally, a residential elevator is the smallest of all elevators and is intended only for use in private single-family residences. Residential elevators are generally installed to make a home accessible for persons with disabilities or the elderly.

Each of the above elevator systems has different building code requirements regulating their installation, operation, maintenance, and inspection requirements. Elevator systems are regulated under various building codes. In particular, the ASME A17 codes are the primary reference for design industry professionals.

Are all passenger elevators and their equipment the same?

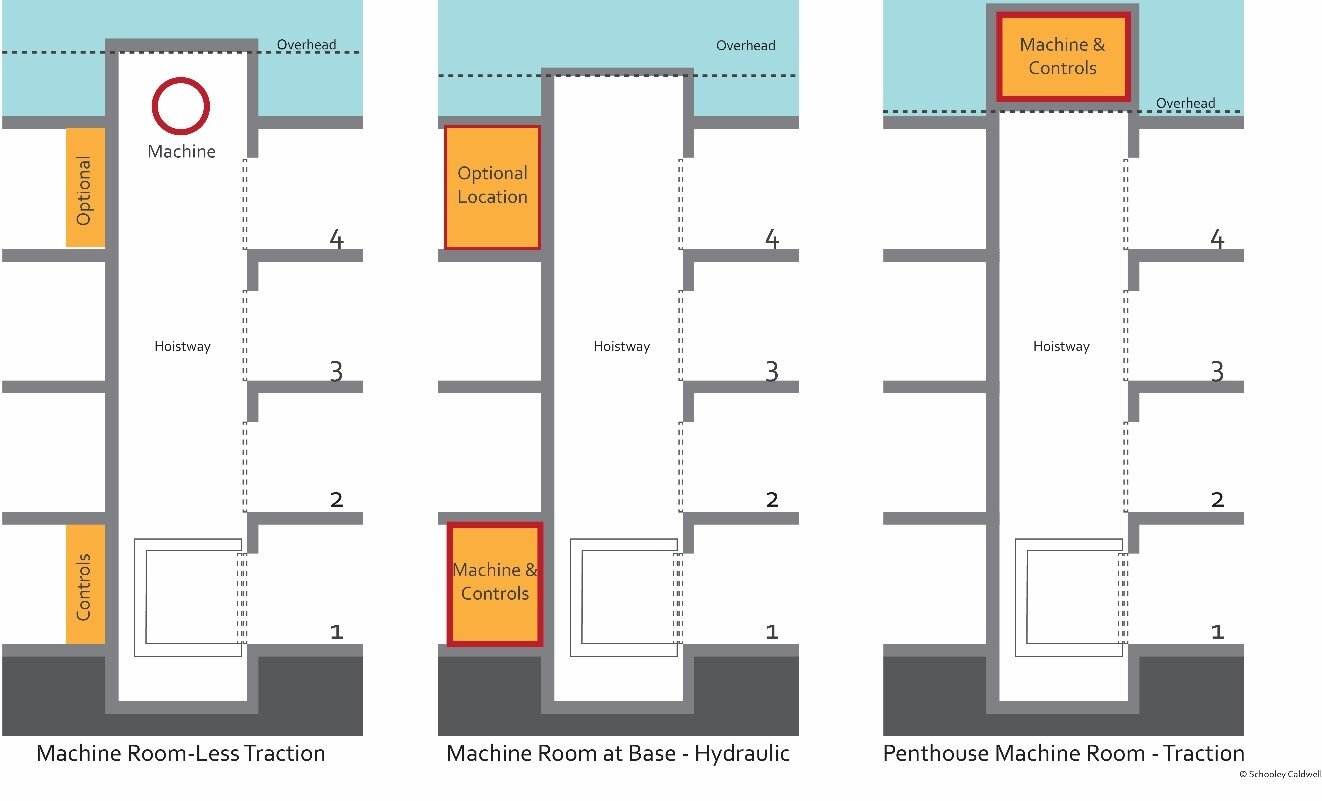

Passenger elevators all function similarly and will have similar building code requirements, but there are different machine types available for passenger elevators. The two basic machine types available are hydraulic and traction machines.

Hydraulic elevators

Hydraulic elevators utilize a pumping unit that pushes hydraulic fluid into a piston that drives the car upward. In most cases, hydraulic elevators will require a small room – around 75 square feet - adjacent to the hoistway to house the pumping unit and/or the control unit. Hydraulic elevators are either “holed” or “hole-less,” which refers to the location of the piston. Each offers its own benefits and drawbacks.

Pros

low overhead

low initial cost

small hoistway size

time tested

easy maintenance access

Cons

bid competition

low speed

noisy

least travel distance

less energy efficient

Traction elevators

In contrast to hydraulic elevators, traction elevators utilize steel cables or steel reinforced belts connected to a car and counterweight that are lifted or lowered by a motor driven sheave. Traction elevators are available in machine room or machine room-less configurations:

Machine Room Elevators

Machine room type elevators utilize a separate room – conventionally located above the hoistway – that houses the traction machine and control equipment. If your project can accommodate a machine room, it is the gold standard in terms of providing good maintenance access, maintaining equipment temperature ranges, and allowing the flexibility to accommodate most performance requirements. Machine room type elevators can serve as few floors as desired or over 100 floors. And because other elevator types are limited in their reach, the machine room type elevators are typically the only option for serving very tall buildings with more than 25 stops. The main drawbacks to machine room elevators are the costs for providing the machine room and the aesthetic impact that a machine room or penthouse may have on the building when viewed from outside.

Pros

bid comptetition

maximum speed

ride quality

maximum travel distance

time tested

easy maintenance access

Cons

initial cost

penthouse required

larger hoistway

Machine Room-Less (MRLs) Elevators

The drawbacks of machine room elevators are the main reason why machine room-less elevators, or MRLs, have become so popular in recent years. Machine room-less elevators utilize a motor that is located at the top of the hoistway, thus eliminating the need for a costly or unsightly machine room. These elevators utilize traction machines that are adapted for smaller spaces and designed to be maintained from within the hoistway. When the maintenance staff needs access to the machine, they must enter the hoistway at the landing above where the car is stopped, ride on top of the car up to the top of the hoistway, and then work on the equipment from the car top within the hoistway. This type of access to the machine is a drawback to using machine room-less elevators.

And although a machine room is not required, a separate controller room around 50 square feet is still necessary in most cases. Machine room-less elevators can only be installed up to around three-hundred feet or 25 landings of travel distance based on today’s technology, and so very tall buildings cannot utilize this type of arrangement.

Another drawback to machine room-less elevators is that they are a relatively new technology in the United States, and so their integration into the marketplace has resulted in occasional hang-ups with building officials and inspectors.

Pros

no machine space needed

bid competition

average speed

ride quality

average travel distance

energy efficient

Cons

largest overhead

newer technology

proprietary

larger hoistway

poor maintenance access

What types of finish options are available in elevators?

Finishes may be one of the most important considerations for many building owners. Unlike most performance-based aspects of the elevator design, the finish selections are the only aspect subject to individual preferences and taste. The finishes used in an elevator can influence the user’s impression of a building and can be used to reinforce company brands, atmosphere, or innovation.

Standard

All manufacturers offer robust lines of standard finish selections that are suitable in most applications. These include door finishes, flooring, wall panels, ceiling panels, lighting, and user interfaces for operating panels and signals. Commonly available finishes include wood varieties, plastics, metal varieties, carpets, resilient flooring, and ceramic tiles. The cost associated with higher end finishes will naturally result in a more expensive elevator system.

Semi-Custom

There are also companies that specialize in affordable semi-custom elevator finishes too, which may be more appropriate for matching styles in historic buildings.

Custom

Designers can also specify totally custom finishes. With custom designs, the sky is the limit in terms of creativity and innovation. But custom designs also require special consideration with respect to material weights, ventilation, flammability, and other such considerations required for building code compliance.

What else should I consider when selecting an elevator?

Shape | Passenger or Service Elevator

There are many optional performance requirements that may impact your final selection. Cars come in passenger or service shapes. Service shape elevator cars (not to be confused with freight elevators) are deep and narrow, making it easier to accommodate long cleaning carts, supply carts and similar lightweight equipment into the elevator car. Conversely, passenger shape elevator cars are usually shallow and wide, making it easier to cycle people into and out of the front of the elevator without getting trapped deep in the back. Both passenger and service car shapes offer the option for a rear door in addition to the front door.

Wait Time

Wait times are a critical consideration in tall or high-traffic buildings. Most people will only wait about 30 seconds before becoming frustrated with the wait time. Factors that affect wait time include the number of floors served, the number of people likely to be calling an elevator at a given time, the elevator’s speed, the elevator’s capacity, and the number of elevators in an elevator bank. For scenarios where wait times may be an important factor, a traffic analysis should be performed by a qualified design professional.

Ride Comfort

Ride comfort considerations include a smooth and quiet ride with minimal bumps. Ride comfort tends to be lesser in hydraulic elevator applications and better when utilizing traction elevators. Hydraulic elevators are noisy, and sometimes produce a scent generated from the hydraulic fluid that some might find unpleasant. But if ride comfort is of paramount importance to the owner, then a traction type elevator may be worth considering. In addition, custom guides, rollers, and other such equipment can be specified to further enhance ride quality.

Structural Support

Structural support is another important consideration. Different types of elevators transmit gravity loads differently, so the building’s structure can affect the elevator type selection. Again, consulting a design professional (including a structural engineer) is a necessary first step.

Maintenance Requirements

In terms of maintenance, passenger elevators need to be inspected annually and pass inspection to maintain a valid elevator operation certificate. And like all building systems, elevators require maintenance to remain safe and effective. If you are an institutional client with many elevator systems to maintain, you may need to consider the manufacturer who holds the current institutional elevator maintenance contract. This may factor into your preferred new elevator system selection. In addition, there are companies that offer non-proprietary control systems that can be serviced by any number of vendors, though specifying these require additional diligence when writing specifying performance and warranty requirements.

Elevator Modernization

Elevator systems that have operated for a decade or more may require a modernization project. Elevator modernization projects typically involve evaluating all existing elevator system components with respect to safety and the most current building code requirements. Evaluations include looking at all the components that are paramount to the safe performance and operation of the elevator. They also involve evaluating accessibility provisions and key engineering support systems. Modernization projects are undertaken when the goal is to renew the lifespan of an existing elevator system.

Dimensions & Bidding

Dimensional planning can also be challenging when competitively bidding multiple elevator vendors. Hoistway sizes and machine or control space size requirements can vary significantly between elevator manufacturers. After a successful bidder has been selected, adjustments to the construction documents may be required in some cases to accommodate the selected manufacturer. In existing buildings, it is also possible that a limited space is available for a new elevator and, in those cases, it may be necessary to eliminate manufacturers with larger system requirements. In addition, utilizing greater elevator speeds will require greater overhead heights and pit depths. This is to ensure passenger safety in case the car slightly over-travels at the highest or lowest landings when traveling at higher speeds. And where elevators connect four or more stories above grade, the building code will require that at least one elevator in the building accommodate an ambulance stretcher. This requirement may result in a larger car and hoistway than would otherwise be required.

Are elevators keeping pace with technological advances in other industries?

New technologies are constantly being introduced into elevator systems. The elevators of today have drastically advanced when compared to early elevators. Manufacturers use technology to gain a competitive edge by introducing innovative features, creating configurations that lower procurement costs, and by creating systems that operate more efficiently.

One such technology is the option to add regenerative drives on traction elevators. In the same way that a hybrid car generates power through the braking system, regenerative drives on elevators capture heat energy during braking and convert it to electrical energy that is transferred back to your building power grid. And like buildings, elevator manufacturers are increasingly programming their elevators to be energy efficient. Turning cab lights off automatically when not in use, going into “sleep” modes, and programming dispatch software to minimize the number of stops required all result in energy savings. And because all new elevator systems utilize microprocessor based controls, the energy utilization is vastly superior to that of older elevator control systems.

Some manufacturers are really pushing the envelope by developing elevators that can move both vertically and horizontally through a building. Although this concept is only in testing, if successful, it could change the elevator design landscape. And while we are a long way away from the Wonkavator used in the movie “Charlie and the Chocolate Factory,” this innovation is an exciting step in that direction.

Note: this article is based on the 2017 Ohio Building Code and corresponding reference standards; however, these standards can change from time to time. Make sure to consult with a design professional for the latest codes and standards for your project. This information is intended to be used for general reference only, so be sure to consult with a design professional to determine what’s best for your project.